BRAZING PROCESS SUPPORT

BRAZING TESTS

Customers are invited to send or to bring us their parts to be brazed at any stage of their production process for design purposes or for in-production quality issues. We support them to determine the ideal brazing paste as well as the ideal heating parameters.

In general, the success of a brazing operation is not only dependent on the selection of the solder, but is also the result of a combination of various factors including the choice of the base materials and joint design. Therefore, a discussion with the customer about all these factors is an essential step toward the final result of a successfully brazed joint.

Do you want to know more about brazing tests?

Contact us

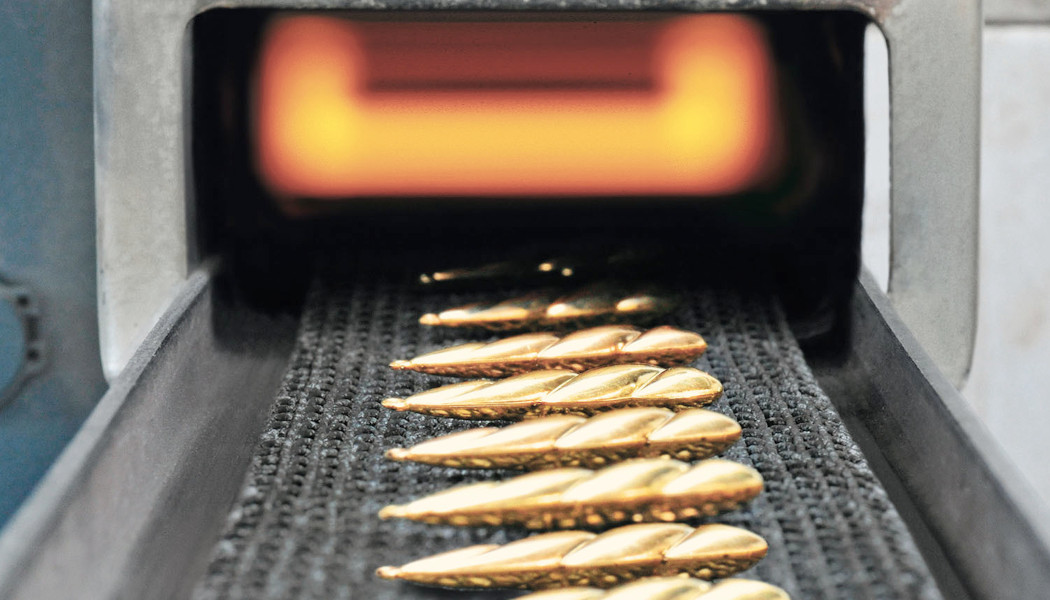

FURNACE UNDER ATMOSPHERE

Our belt furnace, which is equipped to work with various protective gases such as cracked ammonia, a mix of hydrogen and nitrogen, pure hydrogen or argon, can be rented by day or half-day. One customer may prepare his parts at his workplace and then come to our office to pass them through the furnace. Another one may desire to use the furnace to make preliminary tests before deciding to buy his own or to look for a subcontractor.

Want to know more about Furnace under atmosphere ?

Contact us

ATOMIZATION PROCESS SUPPORT

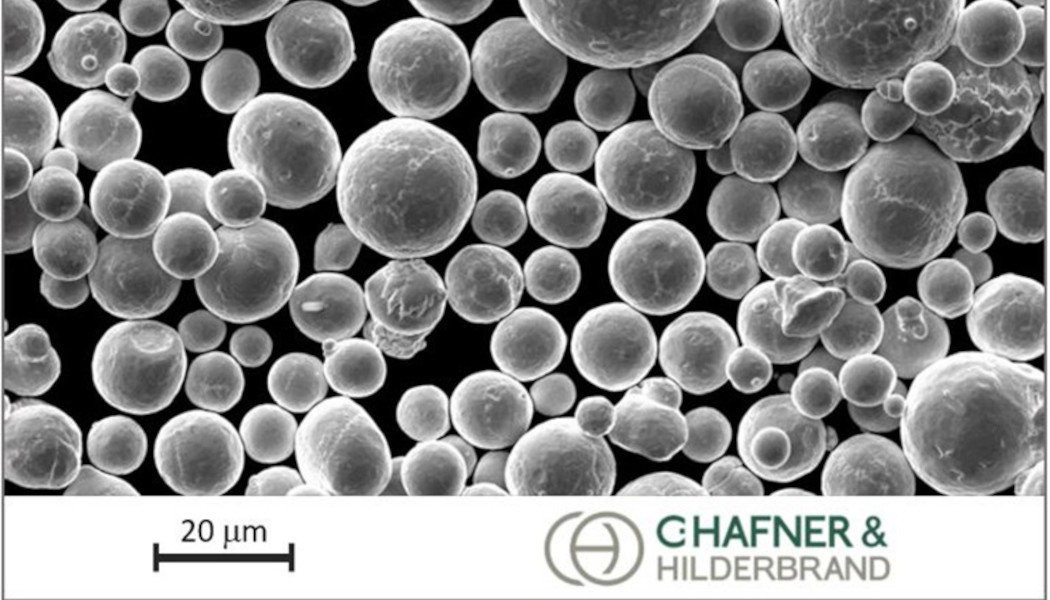

METAL ATOMIZATION

We can atomize precious metal alloys using various gas atomization techniques. If you don’t find your exact composition in our portfolio or if you have a specific alloy that you want to make into a powder, contact us and we will atomize it for you.

For more information about Metal Atomization

Contact us

SCREENING & PARTICLE SIZE MEASUREMENTS

Our metal powders are available with several particle size distributions, usually from 0 to 106 microns. If you need a specific particle size, we can fine-tune the distribution according to your specifications using screening methods.

The particle size range can then be adjusted to suit your requirements. Our complete range of certified sieves enables us to provide powders with particle size as fine as ±20 μm up to ±200 μm. By classification we can extend the sieve range, especially for small diameters. Particle size distribution reports by laser diffraction analysis from 0.1 to 700 microns are also provided.

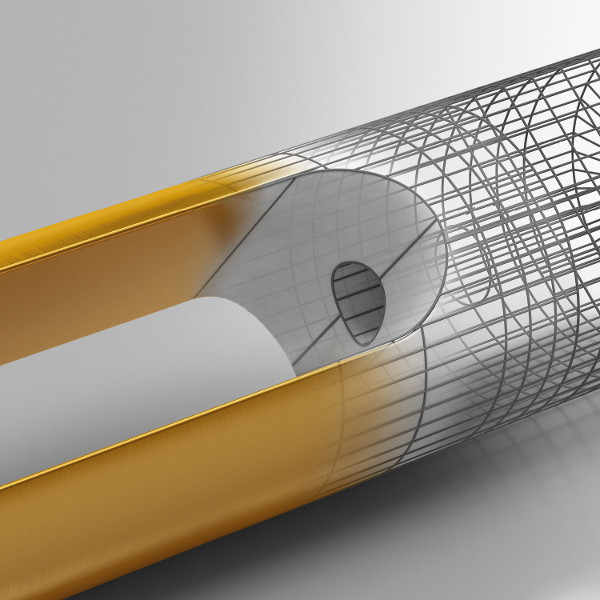

CUSTOM-MADE COMPONENTS

FROM DESIGN TO FINISHED PARTS

Industrial applications almost always require customized solutions. This includes the production of new alloys with precisely defined physical or chemical properties, precision parts with high levels of dimensional accuracy or new, previously unknown combinations of materials. With C.HAFNER & HILDERBRAND as a leading system partner for precious metals, our customers receive the entire material and production spectrum from a single source.