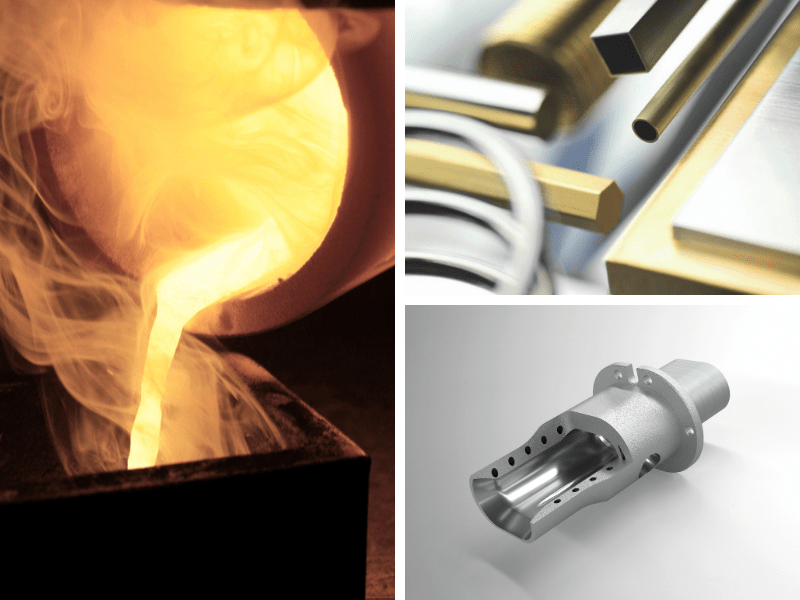

Casting

The melting and casting of precious metals is an important element of both refining and semi-finished products. Depending on the requirements, different melting and casting systems with integrated data acquisition for process control and management are used to ensure the quality requirements are met:

- Continuous casting

- Vacuum casting

- Gravity die casting

- Granulation

- Powder Atomization

Melting in a protected climate to prevent oxidation and casting with individual parameters depending on the alloy, guarantee a uniform casting quality for

- Homogeneity of the composition and adherence to the guarantee precious metal content limit

- Uniform casting structure, free from cavities or bubbles

- No inhomogeneities, inclusions or foreign materials exact form and dimensional accuracy

Semi-Finished Products Technologies

On the basis of alloying, melting and casting products, forming processes is an important component of the added value for the production of semi-finished products. The desired product properties are set by different available forming processes and heat treatments. Complete production lines are used for sheet metal, wires, tubes and rods by :

- Rolling

- Hammering

- Pulling

- Straightening

- Tooling

- Sawing and cutting

For heat treatment, we use the chamber, conveyor and strand furnaces for various intermediate and finished products.

Annealing treatments include :

- Recrystallisation annealing with or without rapid cooling

- Stress-relief annealing

- Solution annealing

- Precipitation annealing

Thanks to high production capabilities, we can supply a complete range of precious metal products in the desired quality. Individual specification of the technology in work schedules always guarantees consistent quality and reproducibility.

CNC MACHINING

Our CNC technologies are based on our metallurgical expertise and forming processes that allow us to produce preliminary products for CNC processing. We manufacture customised products made of different precious metal alloys using a wide variety of technologies such as :

- Long and short turning from Ø 0.2 – 52 mm

- Milling on various CNC milling centres

- Water jet and laser cutting

- Laser labelling for traceability

- Hybrid processing of near-net shape SLM components using CNC technologies.

HYBRID PRODUCTION TECHNOLOGIES

Most workpieces printed by means of powder bed technologies are predestined for post-manufacturing stages. Desolidarization from the manufacturing platform and support removing lead to a semi-finished near net-shape 3d printed product. The prerequisite for any post-processing is a fine microstructure which is achieved using the SLM process.

For jewelry items, once removed from the machine, the product is ready to be polished according to the project designer. For watchmaking or other industrial products, parts require common CNC post-processing techniques available at our facilities. Finally, depending on your personal wishes, the product can be delivered at any stage from as-printed to ready-to-polish state.

PROTOTYPING

To turn ideas into reality, prototyping precise industrial parts made of precious metals for jewelry, watchmaking industry or any other industrial field is made possible by the combination of 3D printing technology by selective laser melting and subsequent CNC machining.

From your design and drawing, we take over the full process to ready-to-polish finished product. Whether for 18k colored carat gold alloys, palladium or platinum alloys we can support you even if you are an individual interested to start with a single product or a major manufacturer looking for products designed for additive manufacturing with increasing volumes.