Internationally recognized for innovative brazing pastes and powders

- Switzerland

- Europe

- RoW

Watchmaking

Watchmaking

Firstly, we serve the most prestigious brands, making brazing a technology that meets the highest standards. Secondly, we complemente our offer with precious metal solutions meeting manufacturing needs from alloys to customized finished parts.

Jewelry

Jewelry

Each craftsman from the single jeweler or from the jewelry industry enjoys HILDERBRAND® brazing solutions. He will also find precious metal alloys and customized solutions to support its creativity.

Industry

Industry

Hilderbrand® precious, non-precious & active brazing products are designed to meet the most stringent industrial needs. We also provide customized parts made out of premium quality precious metal alloys.

Medtech

Medtech

Brazing solutions typically for surgical instruments. We provide techniques for joining various material combinations using our precious, non-precious, or active brazing solder pastes. In addition, we provide precious metal alloys for medical devices.

Watchmaking

Firstly, we serve the most prestigious brands, making brazing a technology that meets the highest standards. Secondly, we complemente our offer with precious metal solutions meeting manufacturing needs from alloys to customized finished parts.

Browse brazing pastesJewelry

Each craftsman from the single jeweler or from the jewelry industry enjoys HILDERBRAND® brazing solutions. He will also find precious metal alloys and customized solutions to support its creativity.

Jewelry productsIndustry

Hilderbrand® precious, non-precious & active brazing products are designed to meet the most stringent industrial needs. We also provide customized parts made out of premium quality precious metal alloys.

Industry ProductsMedtech

Brazing solutions typically for surgical instruments. We provide techniques for joining various material combinations using our precious, non-precious, or active brazing solder pastes. In addition, we provide precious metal alloys for medical devices.

Medtech Products Brazing pastes and powders

And other Innovative solutions

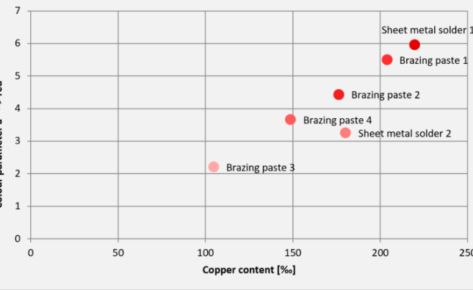

Brazing pastes

Brazing pastes

High-end brazing / solder pastes for carat & hallmarking, medtech & industrial applications

Semi-products

Semi-products

We produce precious metal products including sheets, wires, tubes, profiles, casting shots & powders for luxury and industry

Custom components

Custom components

From the idea to the finished precious metal component. Our integrated solution

Recycling

Recycling

Material that needs to be recycled? You can hand in all your precious metal scraps to C.HAFNER & HILDERBRAND for refining!

Brazing pastes and powders

And other Innovative solutions

Brazing pastes

High-end brazing / solder pastes for carat & hallmarking, medtech & industrial applications

Browse brazing pastesSemi products

We produce precious metal products including sheets, wires, tubes, profiles, casting shots & powders for luxury and industry.

Browse semi productsCustom components

From the idea to the finished precious metal component. Our integrated solution.

Browse custom componentsRecycling

Material that needs to be recycled? You can hand in all your precious metal scraps to C.HAFNER & HILDERBRAND for refining!

Recycling policy